How To Install Metal Roof Covering Metal Roofing System Installment

By understanding common difficulties and having repairing approaches in place, you can avoid unneeded hold-ups and setbacks. This section offers insights into several of the typical concerns faced throughout metal roof covering installation and uses sensible options to overcome them. By collecting the ideal products and devices, you established the foundation for an effective roof covering job.

Bend Trim Ends Shut

Measuring And Cutting

Listed below, we'll discover some constant errors, give functional steps to avoid them, and clarify why these steps work. Sealants and flashings are additional safety measures to obstruct water entry and secure the integrity of the roofing system. Nevertheless, the procedure entails careful preparation and execution to ensure the roof covering executes efficiently. I was a roof covering fabricator for two decades, before making a decision to start myrooff.com and collect the very best web content about roof covering. I like woodworking and building and construction and it was just all-natural for me to begin this passion task of mine.

- To set up ridge caps, initially measure the length of the ridge and reduced the ridge caps to size.When discovering just how to set up a steel roof, understanding safety and security is one of the most essential action.Before you begin, make certain your roofing framework is sound and correctly covered.Wagler Steel is below to support you every step of the means with high-quality steel panels, professional suggestions, and tailored recommendations.

Past the fundamental setup procedure, there are additional ideas and alternatives that can boost the performance and durability of your steel roof. Recognizing these aspects is critical for keeping your roof in the long term. This area explores various approaches and choices to guarantee your metal roofing stays in leading problem. Installing a steel roof covering on your shed is a task that needs cautious planning and execution. With the ideal guidance, you can attain a professional-looking outcome that improves both the performance and appearance of your shed. This area provides a detailed, detailed overview to aid you via the Extra resources installment process.

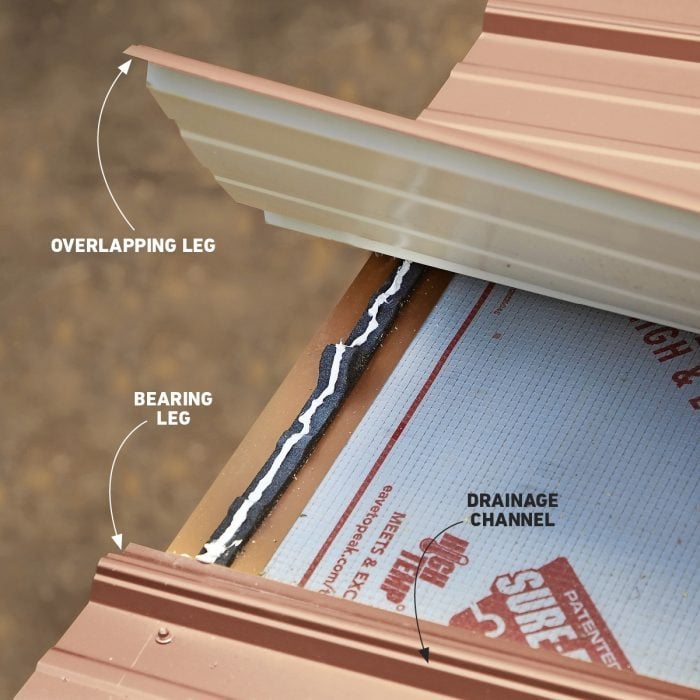

This guide will instruct you about the sorts of metal roof covering and give you step-by-step directions on steel roof installation for a standard corrugated through-fastened metal roofing. Inappropriate overlapping of steel panels can bring about water infiltration, which can damage the roofing system structure in time. Installing steel roof can be a fulfilling project that uses resilience and effectiveness.

It is normally made of galvanized steel or light weight aluminum and is readily available in different sizes and shapes. To mount blinking, initially determine the length and size of the area that needs to be covered. Set up ridge caps at the roof's peak and usage flashing to seal any kind of openings around vents, chimneys, or various other roof infiltrations.

The underlayment is a vital component of a corrugated steel roof, as it offers a water-proof barrier in between the roofing system panels and the roofing system deck. It likewise aids to safeguard the roof covering deck from wetness and rot, and it can help to minimize noise from rainfall and wind. For all your roofing needs, consisting of metal roof covering installment, roofing replacement services, and industrial roofing system repair work, count on RSH Roof covering.This action makes sure that your panels will certainly maintain their clearness and long life in time. Setting up metal roof covering is a satisfying venture that can substantially enhance your home's worth and curb appeal. By complying with these actions and thinking about the different sorts of metal roof coverings available, you can successfully mount metal roofing that gives dependable security for years. Choosing the ideal materials is essential for a successful metal roofing installation.

Let's wrap up the essential actions included and discuss why these actions are advised. Choosing premium products enhances the roofing system's capability to hold up against rough climate condition and stops constant replacements. Flashing ought to be installed around any type of roof covering penetrations, such as vents, chimneys, and along the valleys and hips of the roofing system. This helps direct water far from these at risk areas and is necessary for preventing leaks. These preparations aid produce a smooth, safe base for the steel panels, minimizing the threat of Homepage installation mistakes and future leakages. Below, we'll go over the necessary tools and materials required for the work and describe why each is essential in guaranteeing a successful installation.